Custom Plastic Injection Mold-Making Services

Count on our Expert Engineering Team of Custom Mold Makers

Custom Plastic Injection Mold-Making Services

Stelray Plastic Products offers complete custom injection mold-making services and accepts existing mold transfers all managed by our expert engineering team. Our staff is committed to achieve optimum tooling performance and cost-effective savings. As custom mold makers, we offer in-house design and long-term mold service maintenance, as well as enhancements for new product needs.

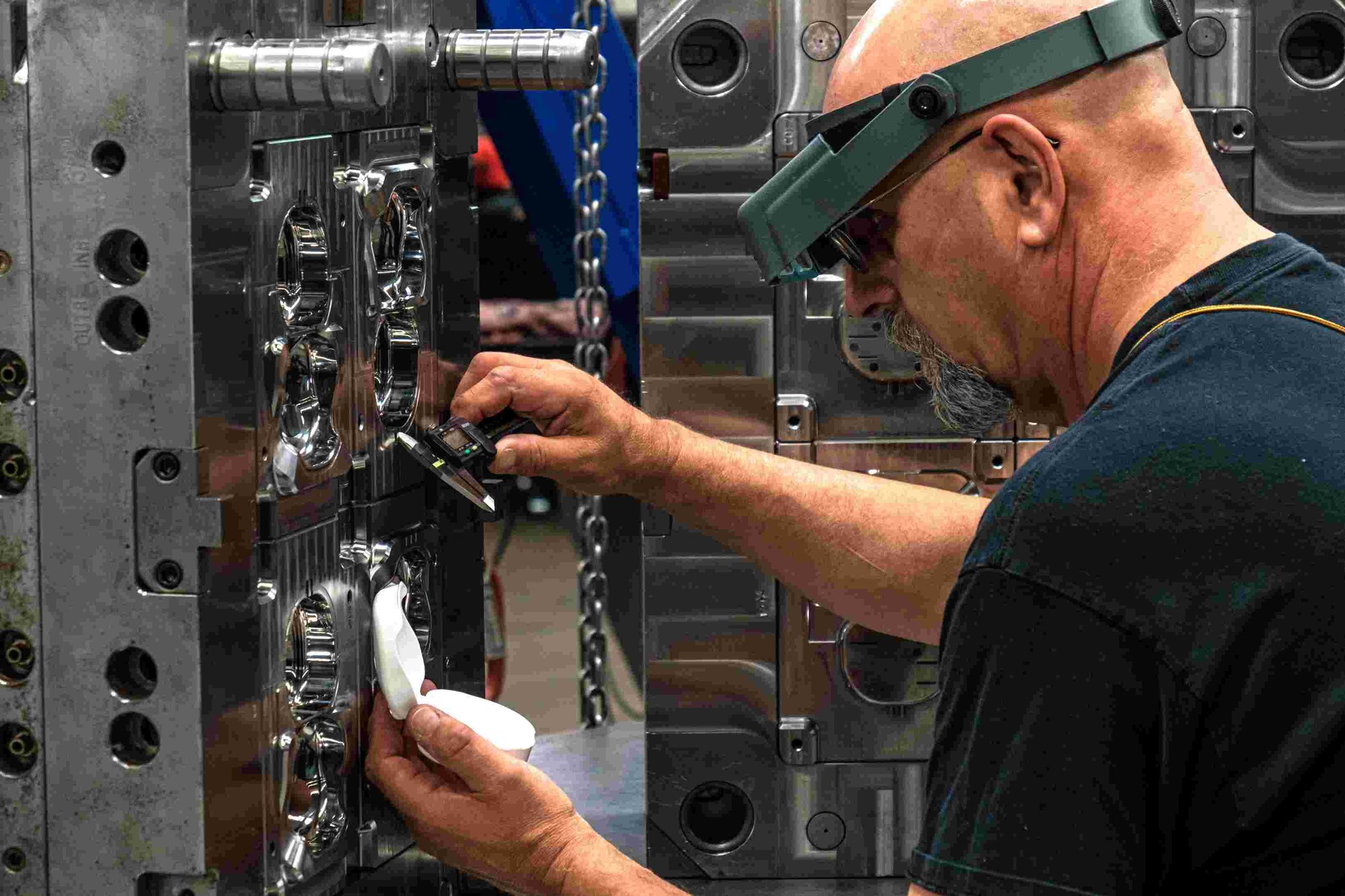

State-of-the-art CNC machining centers and EDM technology combine with the skills of our experienced mold-makers to meet your tool build and finish requirements. Our services consistently deliver molds that result in high-quality custom plastic injection molding, as demonstrated by our outstanding supplier record working with an array of top U.S. and international brands.

Become part of the Stelray custom plastic injection molding team!

Full-Service Mold-Making Department

As a full-service company, we offer in-house design, tooling and engineering support as part of our custom mold-making capabilities. All tooling design and manufacture is done by our team—for a complete custom application. Our engineering staff and machine technicians are experienced in commodity, engineering, to exotic resins, to help guide you in developing the mold best suited to accommodate the material selected for your project.

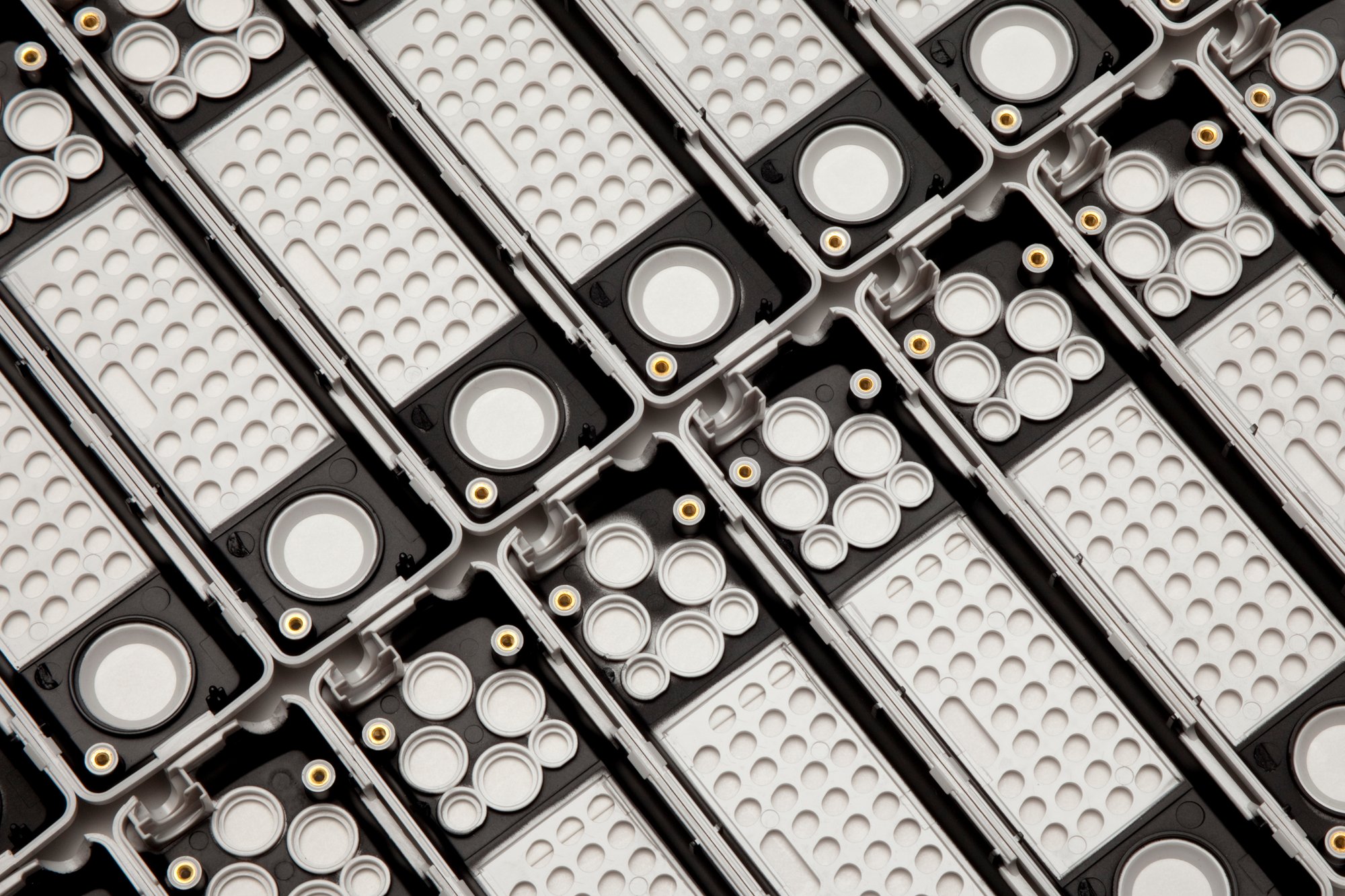

Our custom injection mold-making capabilities start with a comprehensive design review of the product and the pending mold layout to ensure product quality and tooling functions are addressed. We deliver high-precision conventional molds as well as modular molds (MUD units) through CNC 3D-machining, EDM, polishing and texturing.

Among the backend services, we offer:

- Complete tool history documentation

- Comprehensive mold management

- Inspection fixtures custom engineered and built in-house

- Preventative maintenance schedule to stay ahead of damage and wear

Custom Plastic Injection Molding

Our mold-making service begins with in-house design and mold fabrication with quick-turn tooling to get your project to market quickly. We offer quick-turn soft tooling as well as high-production volume hardened tool steel molds in a wide selection of materials, including aluminum, stainless steel, and various grades of tool steel. (Interested in what mold classification fits your manufacturing needs? Click here to read our Mold Class Specification blog)

Whether you have the need for a 3D prototype, are updating an existing component or are changing your manufacturing product altogether, a quality mold from Stelray is the solution.

When beginning a new project, we always suggest ‘early supplier involvement’ to allow our customers leverage our years of plastics and molding experience, our network of industry supplier resources, and mold design and building expertise to ensure that your end product is completed quickly and efficiently.

To learn more about our custom precision plastic injection mold-making processes and services, get in touch with our team or download our brochure.